Why does the PCBA processing still require manual soldering treatment?

In the production process of electronic products, PCBs are transformed into PCBA after SMT mounting, DIP insertion, reflow soldering, wave soldering or manual soldering. Why […]

In the production process of electronic products, PCBs are transformed into PCBA after SMT mounting, DIP insertion, reflow soldering, wave soldering or manual soldering. Why […]

The Conformal Coating was initially only applied to printed circuit boards in the high-tech field (automotive industry, aerospace, and aviation). Due to the increasing use of […]

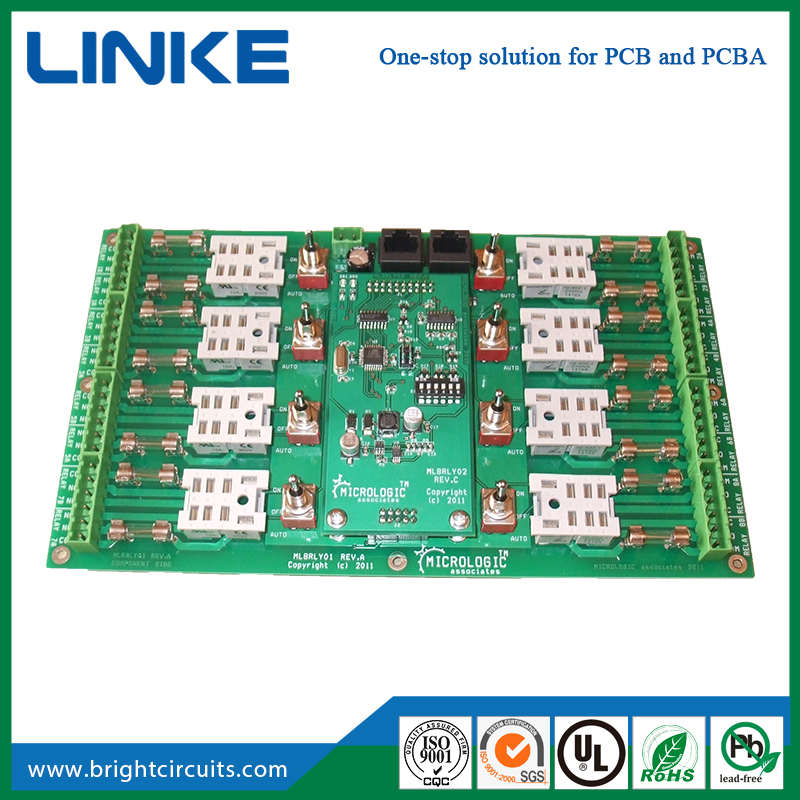

550pcs PCBA boards are shipped to Norway. FR4 material 2 layers PCB board surface finish is HASL no lead free Green solder mask,white silkscreen The […]

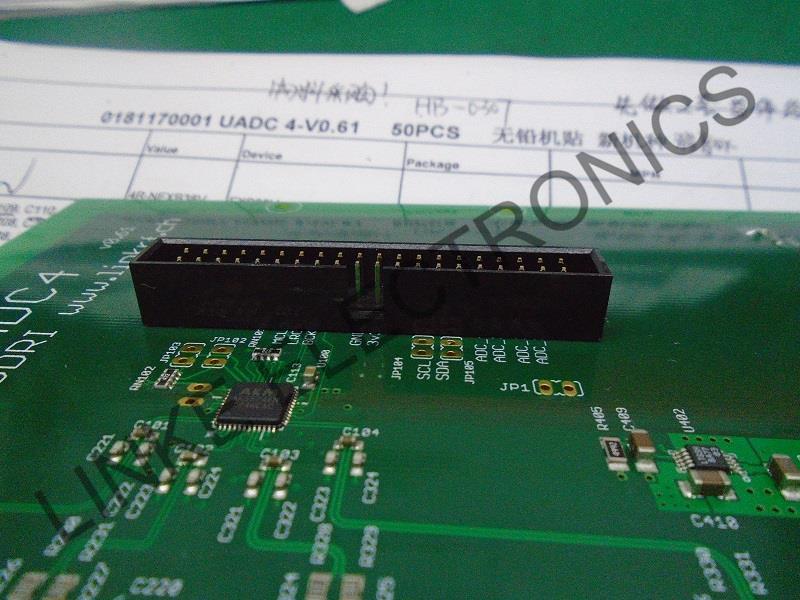

FR4 material 4 layers Immersion Gold 150.00*153.58MM Green solder mask,white silkscreen 1OZ copper 1.6mm PCB thickness 50pcs shipping to Canada.The lead-time is 30 days,all components […]

Wave soldering is a batch soldering process used to manufacture PCB circuit boards, mainly for the soldering of through-hole components. So, what are the issues […]

How to make sure the SMT process is good and fast? In fact, human and material factors each play a part. The human part is […]

The quality and production efficiency of SMT patch processing are very critical for PCB circuit boards. If they are the foundation of PCB circuit boards, […]

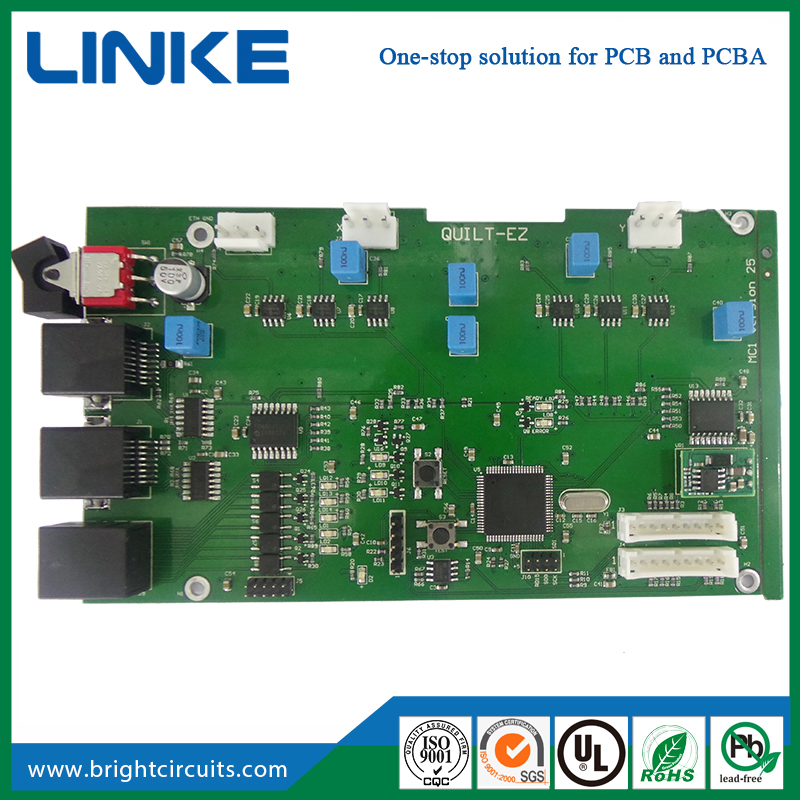

The demand for Prototype PCB Assembly has always occupied an important position in the electronic assembly industry, such as the testing of new products, the […]

If you want to achieve multi-function simultaneous operation on a small circuit board, it cannot be done with a bare PCB board alone. The bare […]

With the development of electronic processing technology and electronic technology, the overall demand for PCB is increasing. Many PCB manufacturers used to only provide PCBA […]

Copyright © 2024 PCB Assembly | WordPress Theme by HEX-V2